PLANEX System® - paddle vacuum dryer Back

Products

www.italvacuum.it

www.italvacuum.it

Description

Planex System is based on an innovative philosophy of working, especially suitable for vacuum drying of wet powders obtained from centrifuge or filter press and it is directed to Active Pharmaceutical Ingredients, Fine Chemical and Intermediates treatment.

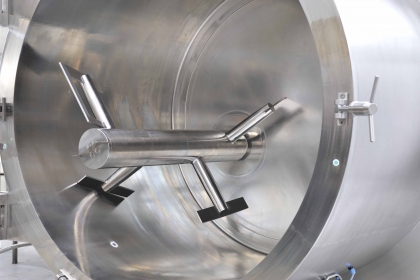

Planex Systemconsists of a fixed cylindrical chamber with an eccentric agitator inside with two independent movements, able to rotate on its own and tangentially to the cylindrical chamber as well. The double combined rotation allows an optimal mixing of the product, continuously renewing the surface of the mass exposed to evaporation, covering all the volume of the vessel. In this way solvents release is facilitated and drying times are significantly reduced compared to conventional systems.

The peculiar configuration of the agitator, characterized by a diameter much smaller than the one of the drying chamber, and the double rotation not only allow the continuous revolution of the product but also limit the mechanical and thermal stress, preventing local overheating due to friction. This enables to treat even more delicate and thermo sensitive products, as it preserves their purity, avoiding degradation of the dried batch.

Planex Systempresents a high loading flexibility. It is manufactured with total volumes ranging from 300 to 4.400 litres. The loading capacity is function of the treated product and it can vary from 15% to 80% of the vessel volume. Both small and big batches can be treated, covering all the requirements of the chemical and pharmaceutical industries.

At the Italvacuum factory (Borgaro – Turin) a semi-industrial model of the Planex System is available for pilot trials.

Beside the Planex System, Italvacuum provides also all the necessary fittings that complete the plant and that are suitably sized in order to satisfy every process requirement:

· heating and cooling group for the system thermoregulation

· condensation vacuum group with tank for the recovery of extracted solvents

· safety external filtering unit

· high vacuum group (Saurus939 pump)

· control panel with PLC for the management of operative parameters of the drying process, provided with software which could be certified according to title CFR 21 - Part 11, and able to ensure reproducibility of the dried batch and connectable to centralized supervision systems.

Specifications

| Volume | 300 - 4400 litres |